B-1 Wing Sweep System

I look at the search words that people end up hitting my site from, gives me ideas. Tonight I saw two searches looking for information on the B-1 wing sweep system, so I figured I'd talk about it a little bit. Not a scholarly tome, just the practical side of sweeping.

Most airplane wing designs are tradeoffs. You set up your wing for low speed stability or high speed performance, or some middle point. But even with flap systems and leading edge slats, fixed wings are compromises, you have one good flight setting, and many more that just aren't as good.

For many aircraft that's fine. An F-15A jockey could care less about low speed loiter stability, he just wants high,fast, and manuverable. A C-130 pilot wants stable and slow.

But a multi-role aircraft needs more flexibility. Having great variability in the wing configuration has huge advantages in making a single aircraft adept at multiple missions. This not only saves the military (and you the taxpayer) money, it also can create an aircraft that is inherently safer, the pilot can adapt the aircraft to whatever flight condition s/he is in instead of having to operate at the ragged edge of stability at times.

The B-1 is a classic example of the current state of the art of production variable wing technology. The wings at low altitude/low speed are almost perpendicular to the body of the airplane, providing maximum lift (and drag, of course) and the ability to deploy a massive surface area of flaps.

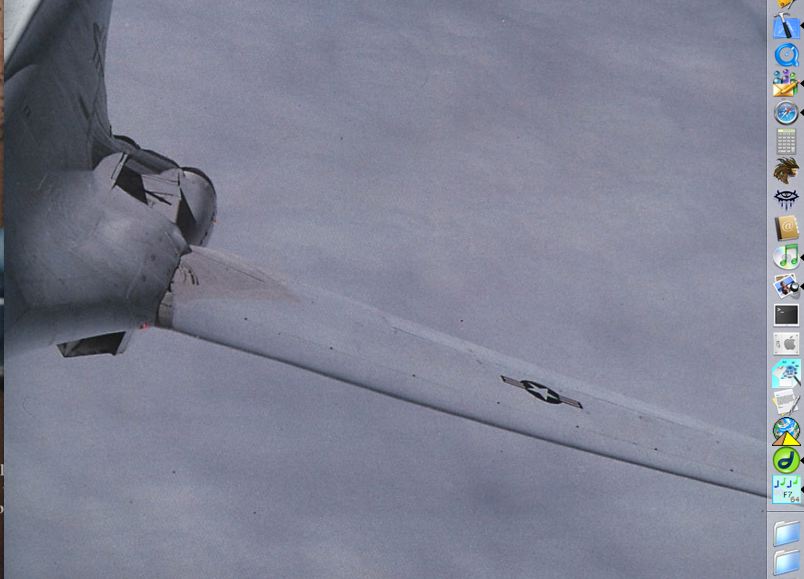

As the aircraft accelerates and climbs, each wing is pivoted aft. Look at the difference with the wings swept aft.

The aircraft now has almost a delta wing, excellent for high altitude and high speed operations. Combine this with the B-1's blended semi-lifting body fuselage and you have a very efficient flying machine that can convert itself into a reasonably comfortable low-speed performer.

And, it's easier than you think.

Here's how the B-1 wing sweep system works, and some of the challenges. The challenges are less than you might think!

Each side of the airplane is symetric, so when I saw "a pivot point" I mean "one pivot point per side", just repeat that to yourself for each component.

First, you have to have the wing. The B-1 wing is skinny and tapered. This is great for being folded against the sides, but not so good at low speed. The wing design compensates for that by having full-length lead edge slats, and very wide and long fowler flaps from the wing root out to about mid-wing. Note that the flaps ONLY work when the wing is swept fully forward! If the wing is at all aft (actually, I think the switches fire off at 4 degrees) then the flaps will not come down. This is a problem if the wing sweep system fails, I've seen one B-1B landing with the wings full aft and it was a doozy, very very fast touching down (the pilot, not a test pilot, did an excellent job).

The B-1 wing was not designed with pivoting weapons hard points, so that complexity was eliminated. The only flight controls a B-1 wing has are spoilers/speed brakes (they are the same surface and actuators), the B-1 does not have ailerons. Another complexity removed. And, half the spoiler panels de-activate when the wing sweeps aft, only the outboard panels still operate. Since that's all the stuff on the wing there are only 8 hydraulic connections on each wing to feed the spoilers. By the way, that's a trivia answer, those are the only hydraulic system hoses on the B-1, all the other connections are titanium tubing (a nightmare itself for maintenance, damn, it can be hard to line up nearly inflexible titanium tubing connections in tight quarters). The wings do contain fuel, so there is one fuel hose connecting the wing to the fuselage. The flaps and slats are driven by flex joint/telescoping shafts. There area few wire bundles for wingtip lights and spoiler wiring.

Now that you have a wing, you have to hang it on the airplane. The mid section of the B-1 is a huge titanium casting that everything else hangs from (in effect), and each side of that casting has the pivot point for the wing. Slide the wing into the slot, then drop the pivot pin in. OK, a little bit more complicated than that. The pivot pin is a huge titanium cylinder almost two feet in diameter and, as you can imagine, almost as long at the wing is thick. It is hollow, the wal thickness being (as I vaguely remember) about 2 inches. It's not hollow all the way through, it has a solid bottom. And this is part of how you put the wing together or take it apart! The pivot pin is designed to have almost zero clearance, tighter than the tighted press-fit. You do NOT want to have slop in the wing pin to allow the wing to flutter! Which makes installation and removal somewhat of a problem. But not really! The solution is to fill the center hole of the wing pivot pin with liquid nitrogen, and keep filling it until the pin and the surrounding pivot hole shrink a little bit from the cold and you can actually pull the pin or drop it back in pretty easily (easily as a relative term). Noting more fun than a bucket brigade of liquid nitrogen, OSHA would have shut us down had they seen it.

The wing is now hung on the airplane. Next step is to move it back and forth. The wing is swept by two major components, the wing sweep actuator and the wing sweep power drive unit (PDU). The wing sweep actuator is a very large (two foot high by 4-ish feet long) that contains a shaft. The cylinder end attaches to the titanium fuselage box mentioned earlier, the rod end attaches to the wing. The actuator has complex and very strong gearing inside that moves the shaft in and out, and therefor the wing fore and aft. By the way, this actuator has to be inspected periodically, and ours had instrumentation attacted, and the only person who was skinny enough to get at it was me. I will admit, the only time I ever thought that they would have to de-skin the airplane to get my butt out was on inspecting the WS actuators, that was a tight squeeze. The actuator itself has no power source, it has shaft power inputs top and bottom that drive the actuator.

The actuator is driven by the wing sweep PDUs. There are two of these, one in each wing root. They have hydraulic motors at the top and the bottom, and they drive the shafts that drive the wing sweep actuators. All 4 hydraulic systems are used, one hydraulic system for each PDU motor.

So it goes: Pilot or co-pilot pulls or pushes the sweep lever on the sidewall of the cockpit. Signal is set to the wing sweep PDU. PDU motors spin, turning a complex series of reduction gears. Those gears turn shafts that spin the gearing in the wing sweep actuators. The wing sweep actuators move in or out, and the wing pivots fore or aft.

Simple! OK, there are a few more issues.

#1 issue: Do Not Try This Without a Wing Load! The system is not strong enough, nor are the pivot points designed, to be able to sweep the wings while the airplane is sitting on the ground with the wings drooping. It's desinged to work when the wing is flexed upwards when it is supporting the aircraft in flight. When the wings are swept on the ground it is critical to have jacks (with wheels on the bases) at the outboard ends of the wings simulating the wing in flight.

#2 issue: You kinda want both wings to sweep at the same rate, it would be ugly to have one wing swept while the other is full forward, other airplanes would snicker at your poor B-1. This could have been accomplished by having one PDU sweep both sides, but that would have been much harder, the PDU would have been massive, you'd be having drive shafts crossing the body, ick. The simple solution is to have a very lightwieght cross-connect controller cable teleflex (similar to the speedometer cable in a car or motorcycle) connectin both PDUs. For the PDUs to operate, the cable needs to turn. Each PDU is driving its end of the cable, so if things are right then the cable spins merrily. If something goes wrong, like one PDU stops for some reason, one end of the cable stops, which means the cable will stop. The other, moving, PDU senses that it can no longer turn it's end of the cable and immediately shuts itself down to insure the wings do not become swept asymetrically. BTW, the failure of this cable (not either PDU or any other part of the system) was what lead to the one wings-back landing I saw.

#3 issue: That wing is heavy. When you sweep the wings, you are changing the center of gravity (CG) of the aircraft rather dramatically. CG position has a great effect on control characteristics and stability aspects of an aircraft in flight, so it is hyper-critical to maintain the appropriate CG during a wing sweep in flight. This is mitigated somewhat by burning fuel from the wing tanks first, reducing the wing weight,. but even empty the wings are heavy. On the B-1, this is (for the most part) handled by pumping fuel from the aft fuel tank to the forward fuel tank (or the reverse), this insures the CG stays within limits. The clever reader will note that this means that the range of wing movement changes when fuel load gets below a certain point, or in different weapons configurations.

#4 Wing fairing issues: This gets little more esoteric than I want to get, so just a passing mention. When you sweep the wing back, the inboard aft part of the wing has to go somewhere. And when you swing the wing back forward the place that part of the wing was can just be an open void that airflow will swirl around, destroying aerodynamic flow. This was challenging, the B-1A models had a great in-flight solution which was insane to perform mantenance on. Had the B-1 stayed a Mach 2 plus bird we would have had to live with that. But since speed was downgraded, as much simpler wing fairing system was designed that was not as efficent in the air, but was much easier to deal with on the ground. And butt-ugly. Oh well.

So that's how the wings sweep. If I can think of any other nuances I'll mention them, and if anyone has questions or wants to correct or amplify on any part, lemme know.

C.K. Haun - - 1/2005 -- back